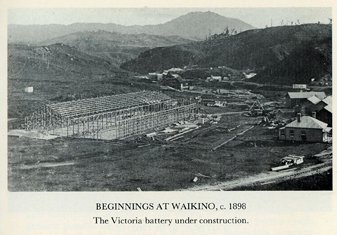

Formed in 1994, our incorporated Society comprises of financial members and volunteers dedicated to promoting and educating the public about this interesting heritage area, which contained huge plant machinery that operated from 1897 to 1954.

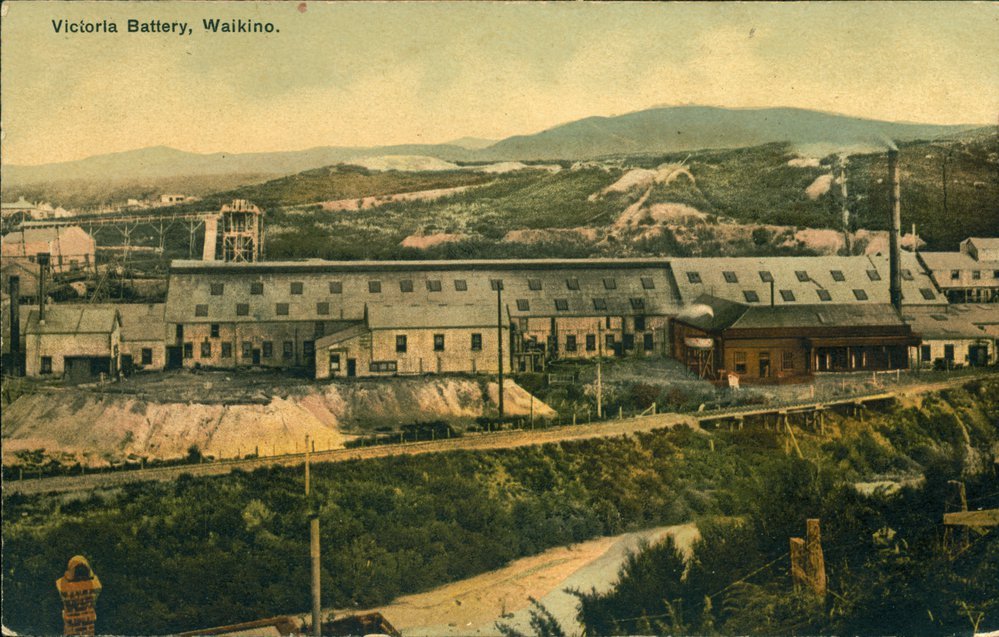

It was the largest quartz ore processing plant in Australasia and one of the biggest industrial sites in New Zealand in the early 1900’s. Then it was the country’s largest producer of gold -10 times more than the next largest battery. Explore the efforts of the Victoria Battery Museum Society Inc. in preserving history in this article.

Our Society provides attractions on open days to give an insight into aspects of the hard rock processing in the good ole tough gold mining days when men worked hard, often in not ideal conditions, for very little pay.

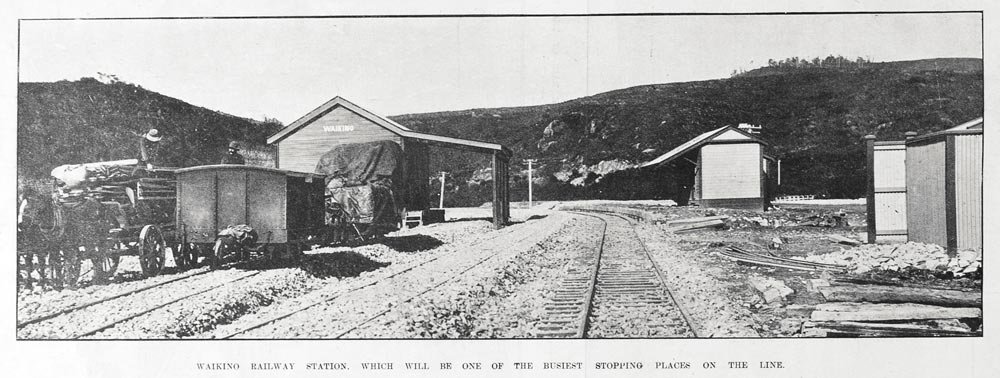

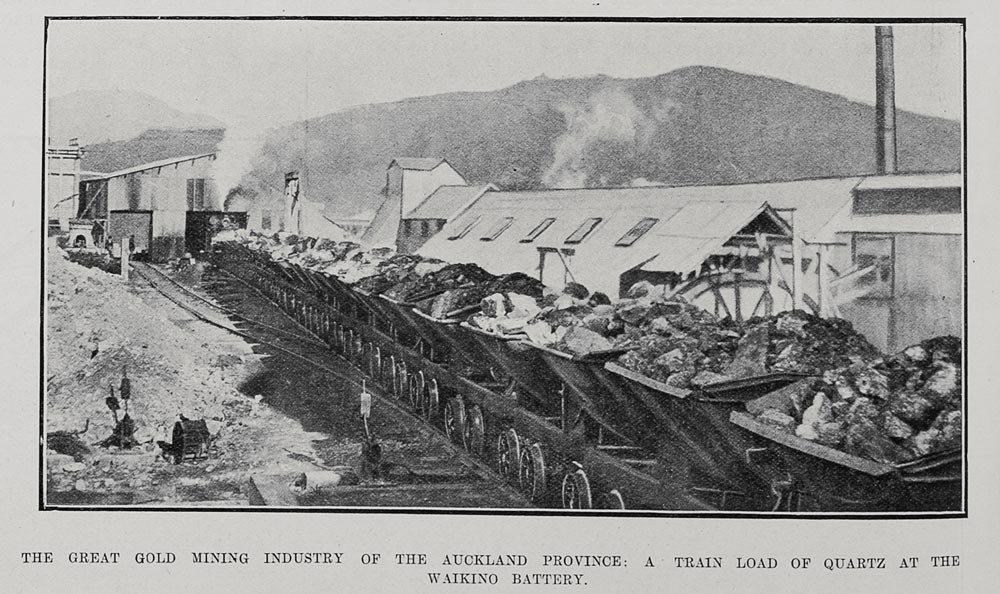

Named after Queen Victoria in her 60th Jubilee year, the Battery had 200 stampers, the largest number at one time of any similar site in the world, crushing on an average of 800 tonnes of ore per day – six days a week. The Waihi Goldmining Company built their Battery at Waikino where ample water was available. Ore was transported by rail on the company’s unique two foot nine gauge “Rake” line from the Martha Mine in Waihi six miles (8 km) eastwards. Drawn by one of the company’s six English-built steam locomotives, 40 skip wagons, each loaded with one tonne of quartz ore were hauled to the Battery site. Normally there were 14 trains daily.

1901 saw the kilns become redundant due to the huge consumption of timber (5 acres (2Hectares) every two days), and a wet crushing process was introduced.

Today the kilns, concrete foundations, steel relics and the Transformer (Sub Station) House are all that remain on this once, huge industrial site.

Up until 1901 the ore was first tipped into large brick-lined ore roasting kilns constructed in the highest point of the Battery site. Alternate layers of 50 tonnes of native timber and ore were stacked into the eight kilns and burnt for a few days, The ore and ash were raked from chutes below into skip ore wagons These wagons were winched through the 200 metre U shaped tunnel and the ore transported on to the crushers, stampers, tube mills and agitation tanks for cyanide treatment, etc. After being through numerous processes the precipitate on zinc filings was returned to the company’s refinery at Waihi for further treatment resulting in valuable gold & silver bars being poured.